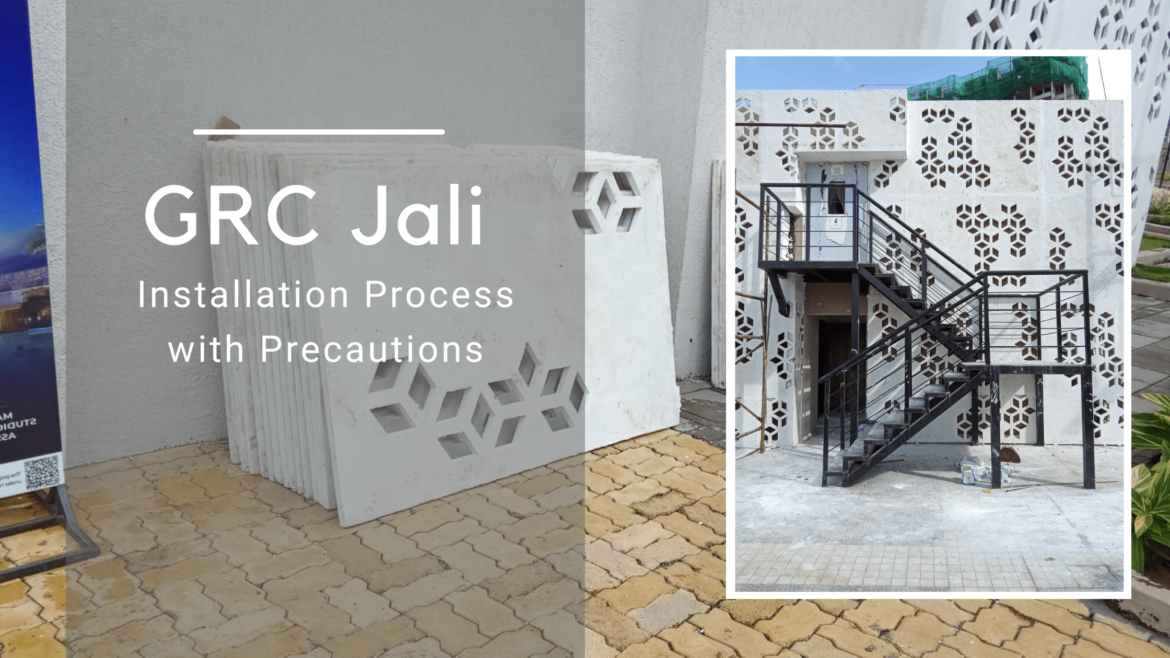

What is GRC Jali?

GRC (Glass Reinforced Concrete) Jali is a decorative and functional architectural element made of a composite material combining cement, fine aggregates, alkali-resistant glass fibers, and other additives. It is lightweight, durable, and offers high design flexibility, making it popular for façade cladding, partitions, and decorative screens.

Key Features of GRC Jali

- Durability: Resistant to weathering, corrosion, and UV radiation.

- Lightweight: Easier to handle and install compared to traditional concrete screens.

- Design Versatility: This can be molded into intricate patterns and customized designs.

- Eco-Friendly: Made from sustainable materials and is recyclable.

- Fire Resistance: Non-combustible material suitable for fire-prone areas.

Installation Process for GRC Jali

- Preparation

- Inspect the site and ensure the supporting structure is level, aligned, and capable of bearing the GRC Jali’s weight.

- Verify the jali dimensions and patterns against the architectural plan.

- Assemble tools and materials such as fasteners, brackets, adhesives, and safety gear.

- Fixing Framework

- Install a sturdy framework (metal, aluminum, or wood) to support the jali. Ensure the framework is rust-proof and securely anchored to the wall or structure.

- Drilling and Anchoring

- Drill holes in the GRC jali as per the design plan.

- Use bolts, screws, or brackets to attach the jali to the framework.

- Ensure the anchors are rust-proof and the fasteners are tight to prevent movement.

- Alignment and Leveling

- Align the jali accurately to maintain consistency in pattern and spacing.

- Use a spirit level to ensure the jali is installed straight and aligned with adjacent panels.

- Grouting and Sealing

- Fill gaps between the jali and the framework with cement grout or silicone sealant to ensure stability and prevent water seepage.

- For large panels, expansion joints may be added to accommodate temperature-induced movement.

- Finishing

- Apply a weather-resistant paint or coating, if required, to enhance durability and aesthetic appeal.

- Clean the surface to remove any installation debris or marks.

Precautions During Installation

- Handling

- GRC is relatively fragile during handling; avoid dropping or applying excessive force.

- Use proper lifting equipment or sufficient manpower for large panels.

- Safety

- Workers should wear safety gear, including helmets, gloves, and goggles, during installation.

- Use scaffolding or ladders safely, ensuring they are stable and secure.

- Anchoring

- Ensure the fixing framework and anchors are capable of supporting the load without bending or sagging.

- Use rust-proof and weather-resistant materials for all fixing components.

- Alignment

- Ensure proper alignment of panels to avoid gaps, misalignment, or instability.

- Check measurements twice before drilling or fixing to minimize errors.

- Weather Conditions

- Avoid installation during extreme weather conditions like heavy rain or high winds.

- Allow adequate curing time for grouts and adhesives under suitable conditions.

- Post-Installation Maintenance

- Inspect periodically for cracks, loose fixtures, or surface damage.

- Clean regularly with non-abrasive cleaning agents to maintain appearance.